Who's Online : 0

Who's Online : 0You know the functionality and the aesthetics which you need but unless your product can be manufactured economically, repeatably, reliably and within the correct timeframes it will never achieve its full potential.

MetalCast’s technical team have been designing successful cast components for many decades. We work in partnership with your product designers to develop and adapt your concept or design to optimise it for manufacture. We use our experience, expert knowledge, and the latest Solidworks CAD modelling and Magmasoft casting simulation software to help us achieve innovative designs in partnership with our customers, which can be manufactured within the controlled parameters required.

Designing castings is a specialist skill. Die cast components require specific features such as draft taper, even wall thicknesses, and the avoidance of undercuts and isolated heavy sections. All of these issues can be easily overcome if you work directly with our team before you freeze your design. Costs of machining, surface finishing and assembly can also be dramatically reduced if we are consulted early in the design process.

1.Provide us with your design concept so far. This can be a finished CAD model, or a rough sketch. We’re happy to sign an NDA if required

2.We will review your designs, and meet with you to fully understand the application and discuss the design and manufacturing options.

3.Using our 3 seats of Solid works ,we will optimise your design for manufacture. We will add taper, gating and ejection points for castings.

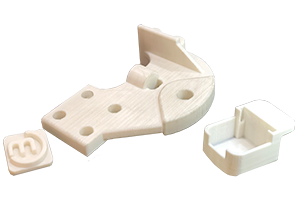

5.We can manufacture prototypes if required, for evaluation, testing, and marketing purposes, prior to committing to production tools.

MetalCast expertise in manufacturing of high grade Copper Based Alloys Ingots & Aluminium Alloys Ingots.

Who's Online : 0

Who's Online : 0